Opportunity Snapshot

- Country:

Russia

Russia - Industry: Energy, Natural Resources, Mining

- Stage: Seed

- Investment size: $30,000,000 / min. $15,000,000

- Type of investment: Debt, Equity

Investment Opportunity

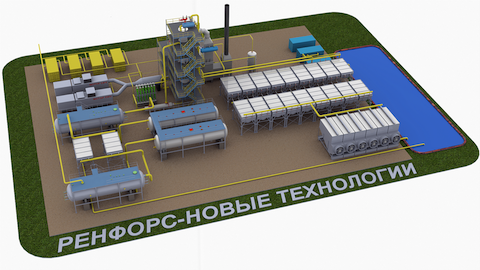

Modular complexes, based on technology GTL, can process gas directly in the fields on land and in sea and river waters during the installation on floating platforms BMC.

The specialists of the company "New Technology" Ltd, bringing together experts from the aerospace and chemical engineering industries from Samara and other regions, with the participation of relevant institutions in Russia, developed technology to mass-produce a block-modular equipment BMC GTL.

Reserves of natural oil, particularly those of good quality, are limited, and in other countries the oil fields are located unevenly across the country.

At the same time, there are vast unused resources of natural gas in countries remote from markets to marketing, with a limited network of gas pipelines and oil fields, construction of pipelines which the uneconomic or physically impossible. In addition, the unused resources of gas is associated gas, burned in flares.

All of these unused gas can be recycled, while receiving transportable, popular foods in the world market - "synthetic oil" and a synthetic diesel fuel standard, Euro 4 and Euro 5, which now occupy more than 1% of the market.

For such a gas processing gas processing technology used GTL (international designation «Gas to Liquids» - gas to liquid). Currently, GTL technology is actively being implemented abroad. Сcompany «Shell» predicts an increase in motor fuel market share of synthetic diesel fuel from the current 1 percent to 15 percent.

In 2006, founded the World Association «ASFE», bringing together the major car manufacturers - «DAIMLER-CHRYSLER», «RENAULT», «VOLKSWAGEN» «TOYOTA», and oil and gas corporation «SHELL» «CHEVRON» «SASOL." The main objective of the association - the widespread introduction of synthetic motor fuel for road transport. Lead testing and certification of civil and military use on synthetic jet fuel company «AIRBUS», «BOEING» and the U.S. Air Force, the company «SASOL» produced in industrial quantities and supplies to the gas terminal synthetic jet fuel.

The specialists of the company "New Technology", bringing together experts aerospace industry, chemical engineering Samara and other regions, with the participation of relevant institutions in Russia, developed technology to mass-produce a block-modular equipment BMC GTL, affordable cost and payback period for most oil companies.

Modular complexes (BMC), based on technology GTL, can process gas directly in the fields on land and in sea and river waters during the installation on floating platforms BMC. In addition to highly, stable liquid transportable products, BMC can receive additional electric and thermal energy for their own needs and production company for the surrounding areas. "Synthetic Oil", resulting from processing, may be mixed with natural oil and transported through existing oil pipelines, oil loading and transport (transport of oil is five times cheaper than transporting natural gas). Further processing of synthetic crude oil directly from the field produces synthetic motor oil with Euro 4 and Euro-5 with a cetane number of 75.

The use of such equipment for the production of synthetic diesel fuel from local sources of gas, which is practically everywhere, it can reduce costs and transportation costs, which is especially important during the development of remote mineral deposits and providing cheap fuel agriculture.

Entering the global market, where such technologies are not available, delivery BMC GTL in countries with gas resources, but remote from markets to marketing, creates unique opportunities to export engineering products.

In fact, it is about creating a new field of high technology chemical engineering-orient

Competitive Advantage

Modular complexes (BMC), based on technology GTL, can process gas directly in the fields on land and in sea and river waters during the installation on floating platforms BMC. In addition to highly, stable liquid transportable products, BMC can receive additional electric and thermal energy for their own needs and production company for the surrounding areas.

"Synthetic Oil", resulting from processing, may be mixed with natural oil and transported through existing oil pipelines, oil loading and transport (transport of oil is five times cheaper than transporting natural gas). Further processing of synthetic crude oil directly from the field produces synthetic motor oil with Euro 4 and Euro-5 with a cetane number of 75.

The use of such equipment for the production of synthetic diesel fuel from local sources of gas, which is practically everywhere, it can reduce costs and transportation costs, which is especially important during the development of remote mineral deposits and providing cheap fuel agriculture.

Entering the global market, where such technologies are not available, delivery BMC GTL in countries with gas resources, but remote from markets to marketing, creates unique opportunities to export engineering products.

Rationale for the deal

In 2006, founded the World Association «ASFE», bringing together the major car manufacturers - «DAIMLER-CHRYSLER», «RENAULT», «VOLKSWAGEN» «TOYOTA», and oil and gas corporation «SHELL» «CHEVRON» «SASOL." The main objective of the association - the widespread introduction of synthetic motor fuel for road transport. Lead testing and certification of civil and military use on synthetic jet fuel company «AIRBUS», «BOEING» and the U.S. Air Force, the company «SASOL» produced in industrial quantities and supplies to the gas terminal synthetic jet fuel.

However, gas processing technology multinationals like «Shell», «Chevron», «Sasol» and others, are unacceptable for small and medium-sized oil and gas companies, as well as provide for the construction of large plants with high cost and long payback periods.

The specialists of the companies' New Technology " Ltd, bringing together experts aerospace industry, chemical engineering Samara and other regions, with the participation of relevant institutions in Russia, developed technology to mass-produce a block-modular equipment BMC GTL, affordable cost and payback period for most oil companies.

Use of financing

Customer Analysis

Equipment buyers are:

- Oil production departments of oil producing companies and their functional units at the production sites: separators, desulfurization equipment, and BMC-10 block-module complexes;

- Power engineering departments of oil producing companies and their functional units at the production sites: power and heat generating complexes;

- Gaspromneftedobycha: separators, desulfurization equipment, and BMC-10 block-module complexes;

- Gasprom JSC for low-yield wells and idle oilfields: BMC-10 block-module complex with power generating units;

- Overseas oil producing companies: separators, desulfurization equipment, and BMC-10 block-module complexes with power generating units;

In case of pessimistic project implementation scenario for oil producing companies, the total annual sales revenue of casing gas processing products is: 63.55 million USD derived from power generation; 48.38 million USD derived from heat generation; and 625,00 million USD derived from synthetic fuel/oil selling.

Annual sales revenue of refining 2.5 million t of synthetic fuel to distillates can be: 1 154.48 million USD derived from diesel fuel sales; 201.58 million USD derived from straight-run gasoline sales; 203.48 million USD derived kerosene sales; with the total sales revenue being 1 559.53 million USD per year.

Looking for similar investment opportunities